It’s not called a Zeppelin unless it comes from the Zeppelin region of Germany, otherwise it’s just a sparkling airship.

I have spent a lot of time writing about building cities on Mars , and I would like to reassure my readers that I have been thinking about other ways to more or less rapidly consume a fortune.

Let’s talk about airships. Yes, they’re hulking behemoths with no real uses and a horrifying safety record. But aside from that, how would you like to get from place to place in a stately fashion? Why cram yourself into a COVID-infested tube at 35,000 feet to zoom around the world in hours when you could promenade the deck while watching the world pass silently from 500 feet or so?

The Pitch: Rebuild the Hindenburg. But better!

Structure

Structurally, I’m going to trust that the Zeppelin engineers knew what they were doing. They built the overwhelming majority of airships that actually worked and didn’t break apart, though the US, UK, Italy, France, Spain, Japan, and Russia all had a go.

But they were built of primitive 2000 series aluminium alloys, doped canvas, and cow gut. I think we can improve on the materials. In particular, carbon fiber pultrusions are about six times as strong and far simpler to assemble than the typical recursive riveted Zeppelin truss.

These beams could be integrated with injection molded nodes and tensioned with Kevlar cables. Gas bags would be aluminized mylar (space blanket) while the outer cover could be ripstop Nylon. (It is hard to overstate just how much better Nylon is than what came before. Try skydiving with a hemp parachute!)

Alternatively, one could optimize for cost instead of performance and cobble together a functional structure from foam core fiberglass produced onsite with simple tooling and assembled like LEGO by hand in the open air.

Alternatively, use a welded aluminium truss segment like the ones used for events. There are about half a dozen manufacturers just in Los Angeles, and while some tooling changes would be needed to support a thinner tube wall, the Hindenburg needs about 20 km of truss.

The exciting thing about the low cost approach is that it closely mirrors the approach of the original Zeppelin designers, who were severely resource constrained. Indeed, with modern materials I think it could be possible to home-build a Zeppelin at a similar scale to the Bodensee for less than $100k and with less than ten person-years of labor. This brings it into the realm of home built yachts and kit aircraft.

Such a home built would have to use innovative manufacturing to be assembled outside a large hangar, perhaps by extruding it tail first from the ground. It may also exploit a more conventional power system with salvaged automotive engines turning propellers in pods. The lifting gas of choice would be hydrogen, in order to keep operating costs low. Provided the space between gas bags and cover is sufficiently well ventilated that hydrogen can never build up at a concentration between 4% and 75%, ignition and/or deflagration is unlikely without a major structural failure or gas bag tear.

Mass

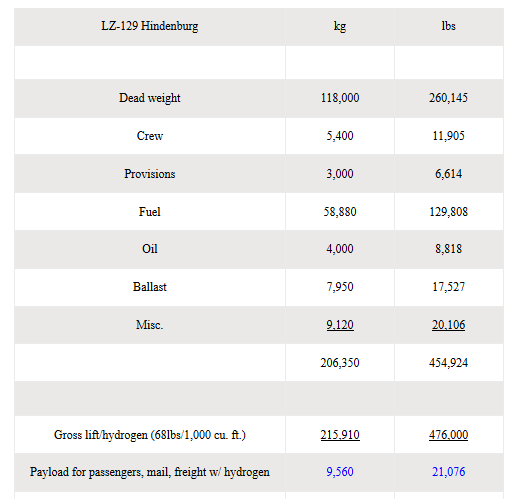

Let’s consider the mass roll up of the Hindenburg.

The structure, at 118 T, is just over half the total lift of 216 T. Doubling structural margins with composites could still reduce overall structural mass by a factor of 3, to 39 T, while also greatly simplifying assembly. That’s less than the weight of a railway carriage! All else being equal, the payload increases from 9.5 T to 88 T, almost a 10x improvement. Payload fraction increases from 4.4% to 40%.

Lifting gas

With all these mass savings we can easily use helium without damaging the lifting capacity. Given that the first Hindenburg burned, killing a third of its complement, non-flammable helium might seem like a no-brainer. At $3 a cubic meter, the airship would cost about $600k to fill. Helium is much cheaper than it was in 1935, but we might want to avoid venting a lot of it, if only to respect the ongoing global helium shortage.

The US Navy built and operated a pair of helium-filled airships, the Akron and the Macon. Without relitigating ancient history, both crashed early in their prospective careers, with loss of life. Helium didn’t make them much safer, and helium-derived design choices may have contributed to their demise. Indeed, relatively few airship accidents involved hydrogen (many of whose fires began with fuel), though it is fair to say that its presence can rapidly make a mess a very hot mess. Hydrogen is about a thousand times cheaper than helium, such that the airship could be refilled every flight if desired. It might even be possible to spike it with fire suppressing gases such as Halon (or less horrible FE-13, between 12 and 20% v/v) without substantially reducing its lifting capacity.

I think a fair design assumption will be helium combined with electrical compressors and storage for trim adjustment in flight.

Propulsion

The Hindenburg had 59 T of fuel and 4 T of oil. Operating with relatively primitive and heavy diesel engines, it could cruise at about 80 mph, crossing the Atlantic in 2.5 days. As it burned fuel it either had to vent hydrogen or capture rain to offset the reduced mass. The earlier Graf Zeppelin used neutrally buoyant blaugas, enabling longer flights over the equator to Brazil since burning didn’t change the weight of the airship.

But there’s no rule saying we have to afford the Zeppelin designers the benefit of copying their propulsion system. Like materials, we can assume that if they had something better, they would have used it.

My suggestion is to affix a steerable electric fan to each structural node. These ~1700 small motors would be able to completely control the boundary layer flow over the airship, stabilizing it in gusty wind and enabling fine-grained control while maneuvering. No need for a big, heavy and structurally vulnerable tail. Many airships were damaged or lost due to gusts while attempting to dock or enter a hangar. No more!

Each motor would be powered during the day by thin film solar panels built into the airship’s skin. This should be able to drive it along at about 50 mph. This number is quite robust to scaling as both drag and power increase as linear dimension squared, while elongating the airship to reduce frontal area both increases structural difficulty and doesn’t actually improve drag.

For additional power or during the night, a neutrally buoyant mix of propane and ethane can be burned in a compact turbine generator. In such a case, range is limited only by what fraction of the envelope is devoted to fuel as opposed to lifting gas. Powering cruise at 50 mph for 7 days would require 33 T of gas, which would consume about 15% of the displacement volume. This increases as the cube of speed.

Use

The original Zeppelins never made money. By the time the Hindenburg flew, all the oceans had been traversed by conventional aircraft, showing the way of the future. While passengers had more space, quarters were still extremely spartan and the walls were literally paper thin, to save weight.

The return of the airship has been mis-predicted many times. Despite hopes, they are not particularly useful for hauling cargo to remote areas. Airships depend on finessed trim and buoyancy – so dropping or picking up a huge cargo load somewhere is a big ask. They’re also not much use near the ground in wind, and no better than alternative logistics methods for delivering containers anywhere.

Nevertheless, we can be optimistic about the return of the airship provided we relax just one assumption – that it will make money. But, like Mars exploration, perhaps it’s possible if only we can find a way to lose money more slowly!

Following mass savings from modern materials, a Hindenburg-sized airship could potentially transport many hundreds of people on regular flights between major cities. In this sense, they look and feel like a cruise ship. A cruise ship of equivalent size costs in the hundreds of millions of dollars to build and also barely makes money, despite exploitation of tax havens and unregulated labor markets.

I think a modern Zeppelin could be built for less than ten million dollars. A small fleet could operate daily flights on a route such as Los Angeles, New York, London, Paris, Istanbul, Shanghai, Tokyo, Seattle. Others could offer specialty tours over the poles or to remote islands, much as cruise ships do today.

Provided one does not intend to hangar them, there is no limit to how big they can be built. Indeed, larger airships have better margins in all kinds of ways. Perhaps the future of sea-steading is in the sky?

Great! Excellent

Bruce Handmer, sent from my iPhone

>

LikeLike

It is unfortunate that in the public mind, hydrogen as a lifting gas is associated with the Hindenburg disaster. Actually, hydrogen filled airships were extremely difficult to set alight. Just ask the Brits in WWI.

The RAF could easily hit the German airships with gun fire, but couldn’t get them to ignite until they developed special phosphorus filled ammunition. They used sustained machine gun fire to rip a section of the gas bags to get the hydrogen to mix with air at their surfaces. Then, the small number of phosphorus burning bullets could ignite this hydrogen air mix. Even then, the RAF brought down very few of them.

Because of this knowledge of how difficult it is to get a hydrogen filled airship to burn, there has been much speculation that the Hindenburg was sabotaged, set to burn deliberately, in a very public act of terrorism / economic / public relations warfare against the NAZI regime (and who could blame them?).

Hydrogen as a lifting gas is more than safe enough. Given the vastly lower cost and the far greater need for helium in other industries, hydrogen would be the lifting gas of choice, were it not for irrational public fears.

Seaby Brown

(Author of “All The Stars Are Suns”)

LikeLiked by 1 person

If the ship doesn’t need a crew, that eliminates (perceived) risk to use of hydrogen as lifting gas. Using hydrogen instead of helium radically reduces operating cost.

Without a crew, without passengers, you have a stately drone carrying bulk cargo to poorly-equipped sites. These could include points at sea, in Antarctica, in undeveloped countries, at natural disasters, and at rural destinations.

An airship might the best possible way to deliver a fully-assembled wind turbine and tower to a prepared pad out between farm fields. Near the base you would have a synthesizer of liquified ammonia, which needs only power, water, and air, that runs when there is wind, producing raw fertilizer and farm-equipment fuel for its host and for neighboring farms.

LikeLike

Hmm … if the desired altitude is only 500 feet, I feel like the best lifting gas could be … air. As in, this “air” ship is a honking huge inflated cone with the passenger deck at the apex and the base floating in the ocean.

It has the stately elegance of a blancmange.

LikeLike

What’s lighter than hydrogen? Vacuum. Let’s not fill the lifting component with anything, just use electromagicnetic repulsion to keep it expanded. Downside: it’s probably impossible. Upside: this probably has no effect on the date at which airships become economically viable.

LikeLike

It’s about 6% lighter than hydrogen and a billion times harder. And burn!

LikeLiked by 1 person

I have often thought about how zeppelins compare to ocean liners in terms of their role and history; perhaps if it weren’t for the Hindenburg disaster and if the company had had a smoother road in developing the things they may have transitioned into a tourist “cruise zeppelin” role later on. More speculatively, I think nuclear power might enable the deployment of truly massive airships; nuclear (theoretically) performs better the bigger the airplane is, and I assume this is also true for zeppelins.

This was a great post; I’m glad I took the time to look it over and read it. I particularly liked the part at the end where you raise the possibility of a synergy between seasteading (skysteading in this case?) and airships. Despite having written whole blog posts (and a painting!) about cloud cities and vehicular seasteads it hadn’t occurred to me to combine a zeppelin or airship with the seasteading ethos. That’ll definitely give me something to think about going forward.

LikeLike

The problem of making hydrogen safe reminds me of measures used by Tesla to reduce fire risk in their lithium ion batteries – keeping the cells apart. Maybe you could have a set of thin-walled vertical tubes holding hydrogen, with helium in between? If some of the hydrogen leaks into the helium, as long as the hydrogen is 8% or less, the mixture isn’t flammable. See http://www.wrightbros.com/pdf/Helium_HydrogenMixture.pdf

LikeLiked by 1 person

Ensure space outside the gasbag is well ventilated.

LikeLike

I’m surprised there hasn’t been more deployment of stratospheric airships for communications and ground monitoring.

If you make them huge with modern motors and batteries they could be very cheap to churn out.

J P Aerospace seem to be very effective at making ultra cheap high altitude airships and are developing now technology for them like said inflatable air beams.

No need to load/unload cargo, no gusts at that altitude etc…

There have been a few high budget failures at this but they are IMO going about it the wrong way. Focusing on using advanced technology rather than going super-massive with high margins and off the shelf tech.

LikeLiked by 1 person

There’s a lot of wind up there!

LikeLike

“Stratolites” appear to have a bright future but they don’t need the precise control of an airship. Loon and the Strat-OAWL have demonstrated that a conventional, non-dirigible balloon can navigate and hold position by moving between different wind currents at different altitudes.

Loon has been regularly launching from Albuquerque, floating to Puerto Rico, and circling the island for weeks at a time. Their balloon uses satellite weather radar to determine local wind currents.

Strat-OAWL from Ball Aerospace is a DARPA project and its flights aren’t known. Each balloon directly observes local wind currents with on-board lidar.

While the balloon location is +/-50km or so, that is precise enough for communications.

As far as I know, there are no actively-funded high altitude airship projects, save JP-Aerospace’s self-funded effort.

LikeLike

Here’s a question that occurred to me a while ago – for what if any planets/bodies in the solar system would a SSTO spacecraft designed to go from the surface to low orbit also be functional as a zeppelin on Earth if its tanks were filled with gaseous hydrogen instead of propellant?

LikeLike

Basically none. Rocket mass fractions are low, but dirigibles are lower still. Maybe 100 times lower.

LikeLike

Doing very rough math and assuming the required mass fractions can magically be attained, a chemical rocket with a similar mass per tank volume as a zeppelin’s mass per gas volume would be an SSTO on Saturn but not Jupiter if filled with hydrolox, and on Neptune but not Saturn if filled with kerolox.

LikeLiked by 1 person

Now do the structural calc!

LikeLike

The Hindenberg blew up because somebody blew up a bomb on board. The flames in the film are kerosene fuel. Most people on board survived even though it fell out of the sky.

LikeLike

Officially, no evidence for a bomb was ever found.

LikeLike

> (It is hard to overstate just how much better Nylon is than what came before. Try skydiving with a hemp parachute!)

Before nylon parachutes were made of silk.

LikeLike

That’s a lot of moths!

LikeLike