Part of my series on countering misconceptions in space journalism.

The SpaceX Starship is a game changer for space exploration. It is intended to be far bigger, cheaper, versatile, and available than any other launch platform. In particular, it is designed to provide for a yearly orbital capacity measured in millions of tonnes. In SpaceX’s world, the days of parsimonious mass budgets and shoestring exploration plans are gone. The mission is to rapidly build a self-sufficient branch of civilization on another planet, and bombarding it with incredible quantities of cargo is a good start. As SpaceX Mars Development Engineer Paul Wooster says, “overwhelming cargo mass covers a lot of sins.”

Despite this vision, some space advocates would have SpaceX modify their plan and develop smaller landing vehicles to stage directly off Starship near the Earth. A mini-Starship would require fewer resources on Mars to return to Earth, albeit with less payload and mass margin. Additionally, a staged Starship could return to Earth in a matter of days, rather than years, increasing its utilization over time.

There are a couple of reasons why, I believe, this approach is flawed. Despite that, it sets the stage for a fascinating discussion about the economics of Starship reuse, which will occupy the latter part of this post.

First, development complexity. The decision-making metric that Elon Musk has adopted has, as its single criterion, the schedule for building a city on Mars. If an action can bring that date closer, that action is taken. Musk believes, based on his experience running SpaceX, that the company works best when focused on as few development projects as possible. Not only does mini-Starship not serve the mission of delivering huge quantities of cargo to Mars, it divides resources, despite some superficial architectural similarity.

Second, payload efficiency and scaling. Generally in rocket design, payload efficiency improves with scale. That is, larger rockets deliver a larger overall fraction of their launch mass. This is because while fuel and payload both scale with volume, there is a certain mass overhead of sensors, avionics, and structural margin that needs to be diluted by a big payload.

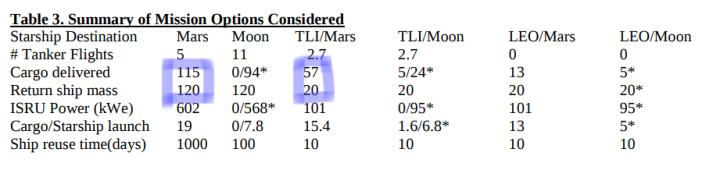

Above: This graph shows that larger rockets generally have better payload efficiency. While the Saturn V delivered about 4.5% of its launch mass to orbit, the Electron delivers 1000x less mass and only 1% of its launch mass.

Even if Starship could be built at two different scales without compromising SpaceX’s limited resources, the smaller Starship would deliver proportionally less cargo per $ invested. As regards flying back to Earth, a propellant plant on Mars needs to produce large quantities of fuel to fly Starships back to Earth. In the grand scheme of things, the most important metric is not fuel per Starship (which favors smaller Starships) but fuel per landed tonne of cargo (which favors bigger Starships).

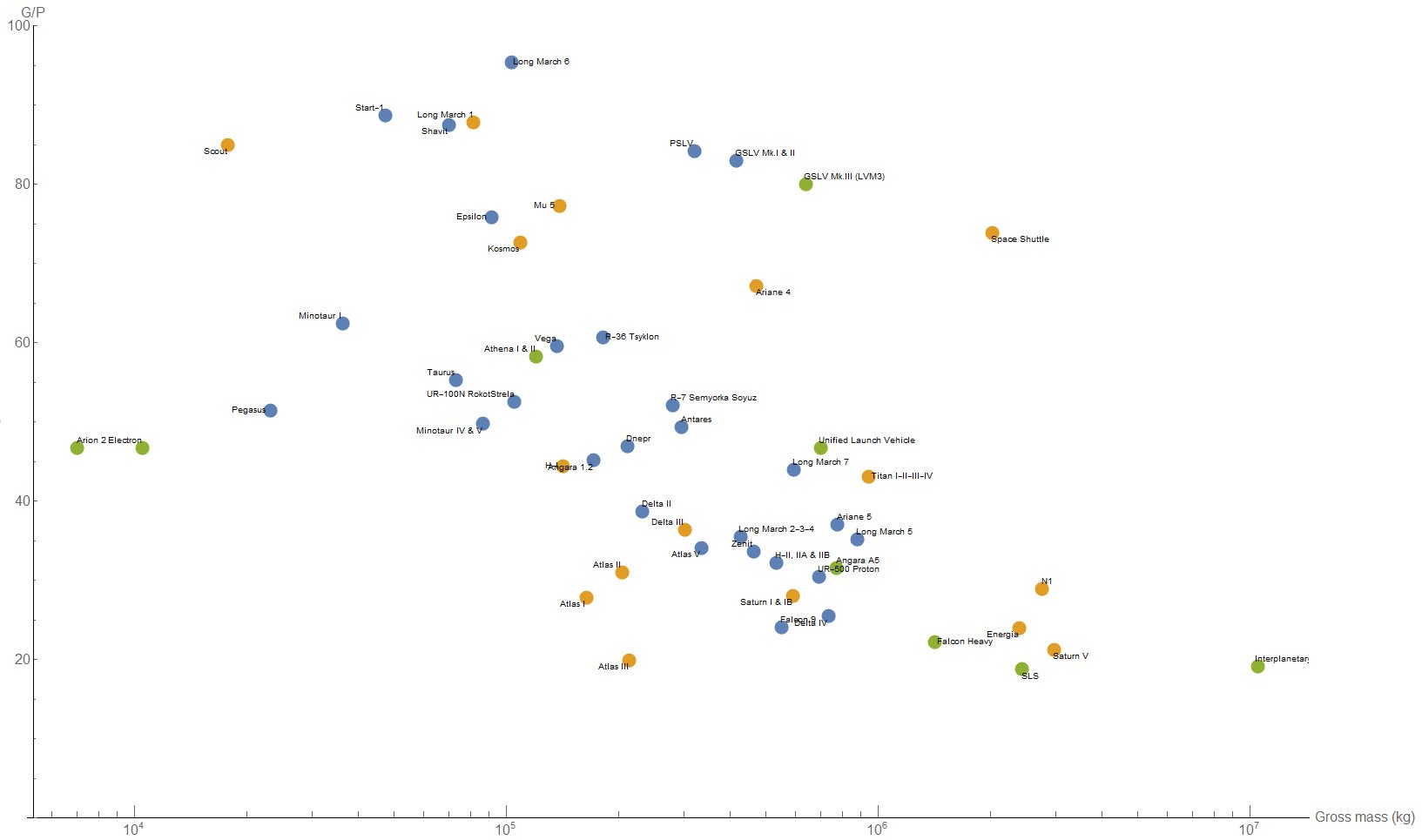

As an example, consider the movement of 1000 tonnes of cargo to Mars. This would require 10 Starships, or perhaps 120 mini-Starships one tenth the size, due to reduced cargo efficiency at smaller scale. If all the Starships are to be returned to Earth, they all need fuel. Even though the Starship requires 10 times more fuel per vehicle, overall the larger vehicles require less fuel for total reuse. In the only published study of mini-Starship, the apparent benefit of the approach is concealed in an unphysically high payload fraction for mini-Starship. Once this oversight is corrected the advantages melt away, as expected.

Above: Table 3 from the mini-Starship paper. Note that the mini-Starship somehow achieves three times the payload fraction of the regular Starship. Without this unexplained, radically unphysical improvement in performance, the supposed benefits of mini-Starship evaporate.

In summary, mini-Starship is just the sort of distracting side quest that the effort doesn’t need. Refilling Starship in LEO is a logistically simplified way to achieve three stage performance from a two stage rocket. The best thing to stage from Starship is itself.

🚀🚀🚀🚀🚀

So, let’s talk about optimal return fraction. In the above analysis, we’ve assumed that all the Starships launched to Mars are eventually returned to Earth. Does this make sense?

In the traditional exploration mode, most hardware is left behind. Yet Starships are very expensive. Getting more than one use can reduce costs and increase total cargo flown to Mars. A more detailed calculation is in order.

The SpaceX plan, c. 2020, calls for the construction of around 100 Starships a year at a unit cost of $5m. Each has an orbital payload capacity of 100 T, and amortizes its construction costs over hundreds of flights. This enables the launch costs to LEO to drop as low as perhaps $20/kg. Recall that about 85% of total LEO cargo is fuel and oxygen to refill Starships to fly to more distant locations.

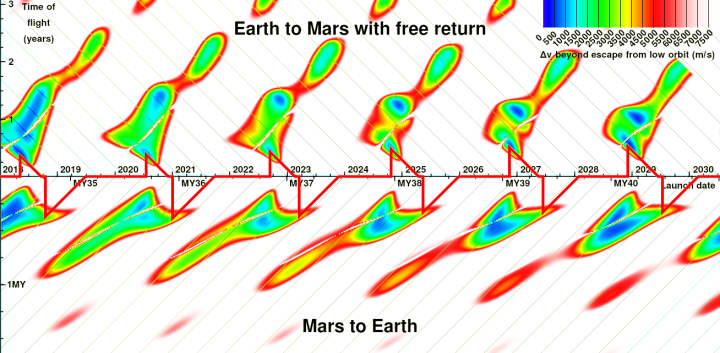

The Earth-Mars launch window opens for a few months every 2.2 years. One Starship can perform the Earth-Mars-Earth round trip during this time, provided it can refuel immediately upon landing and unloading cargo. If it has to wait for the next launch window to return, it can only launch from Earth every other window, roughly every 4.3 years.

More or less continuous launches from Earth stockpile cargo and fuel in LEO until the window opens, at which point a fleet can depart for the red planet.

Above: This graph shows two-way launch windows between Mars and Earth, together with the path taken by a Starship that returns immediately upon landing.

If a Starship tanker can fly three times a day then one tanker can refill about 200 Mars-bound Starships a year. This would imply that most Starships off the line would be the deep space versions, though tankers outnumber Starships off the pad by a factor of about six to one. Super heavy booster construction is unlikely to be the bottleneck.

A Starship in LEO flying one way to Mars can transport 100 T of cargo, and requires about 500 T of extra fuel in LEO to make the journey. Its total cost, then, is $100/kg for fuel and $50/kg for the amortized Starship cost, implying a total delivery cost of $150/kg to Mars before including overhead. The Mars Society city design competition gives a cost of $500/kg, which is in line with other estimates for long term steady state cost, and would imply a transport ticket cost of about $250,000/person, once life support supplies are included.

Let’s say total amortized Starship cost is $100/kg for a one way trip. If we can use the Starship twice, we can save $50/kg while doubling the cargo delivery capacity per Starship constructed. Further uses decrease marginal amortized costs accordingly. How much does it cost to fly a Starship back to Earth? We should expect that at some point, it will cost more to make the fuel than to build a new Starship, representing a local optimum of Starship reuse.

A Starship fully fueled to return to Earth requires about 1200 T of propellant and can transport around 20 T of cargo, flying as a single stage.

Transporting that much fuel to Mars, in the absence of a plant, would require 12 tankers and a long hose. So the no plant baseline increases overhead by a factor of 13. $6500/kg is still a bargain by traditional standards, but the Mars city needs an industrial base anyway, so let’s build a plant.

Synthesizing that much fuel would require about 1 MW of electricity for 500 days, requiring in turn 5 hectares of solar panels. Per Starship, per launch window. At 50 kg/kWe, the solar farm would weigh 50 T. Let’s assume all the rest of the propellant plant weighs 50 T, and the whole thing then fits in a single Starship.

Using the above numbers, the propellant plant would pay for itself (not including depreciation) after 10 flights. Alternatively, given a constant fleet size of N Starships, returning all of them indefinitely would require one launch window be used solely to deliver propellant plants. In my preferred models, however, the number of Starships and the size of the base increase exponentially over time, meaning that it simply isn’t possible to return all the Starships and also deliver any other cargo on the first flight, under the above assumptions.

Let’s take another approach. A propellant plant capable of returning one Starship costs $50m to deploy. If it was used only once, it would save only the $5m cost of a new Starship (assuming production is elastic), which is not worth it. If it is used ten times before replacement, the cost breaks even. Let’s say it requires on average 8% of its mass to be replaced every launch window, implying an ongoing cost of $4m/window. With a return payload of 20 T, the return cargo cost is $200/kg, assuming the savings of reuse are passed to outbound travelers.

Of course, there is one very compelling reason why at least some Starships should fly back to Earth, even if they are cheaply mass produced and there’s no construction rate constraint on cargo upmass. Some humans on Mars might want to come home after a while. Given that an outbound ticket is around $250,000 and a return ticket a bargain at only $100,000, extending a tour by 2.2 additional years could merit a hardship bonus of $350,000, in a currency of your choice!

One other consideration is the starting phase, before any infrastructure is built. In this case some number, hopefully fewer than 10, Starships will have to be sacrificed to bring essential materials before the fuel plant can be built. All of these will be early serial numbers anyway and may be designed for ongoing usage at the base.

In the exponential expansion case, retiring Starships that have done more than three or four round trips will be a small fraction (perhaps 10% or less) of the overall fleet size. Therefore, returning most Starships for reuse will require a substantial reduction in the marginal cargo mass required to increase the size of the propellant plant. In particular, a reduction of solar plant mass to 10 kg/kWe is possible using tensile inflatable structures, while storage tanks can be built from local materials. In all, this reduces the mass requirement by a factor of 10, meaning that any given fleet can be returned with a 10% mass fraction after 4 years, or a 20% mass fraction after only 2 years. The latter case actually delivers more (non fuel plant) cargo due to faster Starship reuse.

Once Starships are reused more than three or four times, their amortized construction costs are a very small fraction of overall shipping cost. Similarly, if construction rate is increasing exponentially, their contribution to overall throughput is an ever diminishing piece of the pie. Therefore I think a strong argument can be made to design for three or four flights and then retirement, in a gigantic Starship boneyard, on Mars. Either way, an exponentially expanding electricity and propellant construction capacity on Mars is a good thing for overcoming downstream constraints on industrial growth.

In the event that propellant plant mass can’t be reduced below 50 kg/kWe, the argument for multiple Starship reuses is weakened significantly. Exponentially increasing Starship production still supports rapid cargo capacity growth, albeit at a rate reduced by a factor between 1 and 2. More generally, for any given propellant plant mass efficiency and rate of Starship construction growth, there is an optimum Starship reuse factor, and a corresponding rate of cargo capacity growth. For example, if Starship production doubles every two years, and the optimal rate of reuse is four, then the net increase in cargo capacity is 1+0.5+0.25+0.125 = 1.875 times the zero reuse case. Even subtracting 20% for plant components, the net cargo throughput is 50% more than the zero reuse case. If building Starships that can fly four times is less than 30% more expensive than building two use vehicles, multiple re-use makes sense in this case.

Finally, one can look at this from a Starship procurement point of view. Let’s say there’s an existing fleet and production capacity on Earth, plus a whole bunch sitting on Mars that only need a load of fuel to return. If we need one more Starship, is it cheaper to make another, expand the factory, or bring an extra one back? If Starships cost only $5m to build, it’s hard to imagine a circumstance where procuring 1200 T of propellant on Mars would cost less than this. And yet if one does the math, cost parity would imply a wholesale electricity price on Mars of only 15c/kWh, comparable to Earth. Oddly, these scenarios aren’t mutually exclusive. Very low cost of power is needed for automated industrialization, which in turn drives shipping demand, and allows relatively inexpensive refueling on Mars for Starship re-use. However, price elasticity also implies that if the marginal costs of increasing Starship production rate are comparable to increasing Mars fuel production rate, that Mars photovoltaic solar panels are in local, mass, automated production. Quite the chicken and the egg!

Starship is a vehicle designed to move cargo in the millions of tonnes. The bigger it is, the better! Even though miniaturized versions turn out to not meet the key requirements, they do motivate an interesting discussion around the economics of reuse on long time scales.

If you manage to get a ship to Mars, then recycling it as building material seems more useful that trying to reuse it for transport.

LikeLiked by 1 person

One ship will bring about 80T of recoverable steel, at an effective cost of about $800/kg, which is above the bulk transport rate, not even considering processing costs. So unless there’s a crushing short term shortage of stainless on Mars, I don’t agree.

LikeLike

Hi Casey, your numbers in the comment above indicate a cost of $64 million for leaving a Starship on Mars. Since the cost of a Starship in the post is only assumed to be $5 million, where is the difference coming from?

Thanks for the excellent post by the way, I love seeing the numbers behind Starship’s potential!

LikeLike

$500/kg delivery cost, essentially construction costs plus overhead. But you raise a good point.

LikeLike

But presumably steel already welded into something suitable as a pressure vessel has some value over raw components. For example, even storage of generated methane justifies the permanent use of some Starships.

LikeLiked by 1 person

Agree.

LikeLike

I think the “starship procurement” model is probably close to reality, and it gives very different numbers than $800/kg. The Starship is already on Mars, owned by Earth. Assume Earth will sell it to Mars at cost. What’s the cost?

If it’s returned, it will need to be refurbished (Musk has said Mars entry will put wear on the heat shield). If that costs $1M then the cost difference vs. building a new one is only $4M.

Returning it will require lots of Martian electricity. Maybe that costs $2M (depends on lots of assumptions). Now Earth only saves $2M by returning it.

If it’s sold to Mars as scrap for $2M, that’s $1M per 40 tons or $25 per kg for the steel, and Mars gets batteries, motors, some solar panels (for in-flight power), and computers for free. I’d think Mars would buy every Starship it could at that rate.

LikeLike

If up cargo and down cargo at Mars was done with smaller Landers and the starship’s mostly stayed in orbit fuel from Mars would be greatly reduced.This would change the entire metrics.especialy for early flights when no cargo other than passengers would be most of the cargo.

LikeLike

Show me numbers?

LikeLiked by 1 person

I agree that Mini Starship isn’t the answer, but can you clarify your analysis of the linked study?

In particular, what do you mean by performance, in reference to payload fraction?

Mini Starship operates as a third stage on the way to Mars and only needs to provide 1.5km/s dv itself. Starship could handle a similar payload fraction (assuming suitably dense cargo) if it staged off a Super Starship and only needed to provide 1.5km/s dv itself.

So I presume the performance issue is for aerobraking and landing at Mars with such a high payload fraction?

LikeLike

A Delta V exchange system could be developed for Mars it could be a space teather system that used Delta V from incoming cargo to supply Delta V exchange to out going cargo.This would greatly reduce fuel at Mars needs.Also with an orbital solar plant could supply power for a colony that is easier and cheaper than a surface system on Mars.

LikeLike

Generally disagree but happy to see your math.

LikeLike

I’m not a numbers guy but the principal’s are sound.A space teather with Delta V exchange and solar power plant would not need the fuel for landing everything remains in orbit in a lazy Geo sincroniss orbit.when cargo is incoming a teather is lowered and attached to outgoing cargo and works like block and tackle the incoming cargo is slowly lowered as the outgoing cargo Is raised the station acts as a fulcrum and any excess Delta V can be used by the station for station keeping.properly designed could result in little need for fuel on Mars end savings would be enormous.Also fuel production on Mars is totally unkown as far as capicty.

LikeLike

The weight of carrying a 17,000 km long tether to Mars geostationary orbit would be prohibitive.

A typical rock climbing rope (assuming 5.25lbs per 40m) that long would weigh over a million kg’s. That’s 10x starship’s cargo capacity to just carry a simple rope.

LikeLike

There are lots of interesting principles and concepts, but the numbers need to be sound. I think that’s how Elon Musk has done so well with Tesla, SpaceX, etc. – he figures out whether the physics and economics both work out. (I’m curious what ideas he’s rejected that others might still be trying.) For instance, the Delta V Tether system sounds quite useful, but is there a reason we don’t already use one here on Earth where it would be even more valuable? Is it the physics or the economics or both that don’t work, or are we missing a tremendous opportunity?

LikeLike

The reason it not used on Earth teather material hasn’t been strong enough and Earth has to many artificial satlites.Both those issues don’t exist at Mars.Also on Earth you can’t beam down your power from the station because you may kill birds and affect weather also not a problem at Mars. Elon may not have looked at this one.

LikeLike

Good post. One more factor in favor of larger starships: Launch site and personnel availability. As you mentioned, launches have limited windows limited further by weather, and limited to certain ideal geographies. It’s cheaper and easier to schedule one big launch than 10 smaller ones.

LikeLike

It could be interesting to calculate/estimate a variant when only the most valuable parts of Starship are being returned (Raptors). Steel is cheap. Electricity production will be very costly on Mars as nicely shown in the blog post.

LikeLike

Or even parts of raptors, factoring in the labor cost of disassembly.

LikeLike

Wikipedia says sea-level Raptors weigh 1500 kg. At $200/kg that would cost $300,000 to ship back.

I’ve seen estimates of $250K per Raptor once they’re built in quantity. At that rate, a cargo of a dozen Raptors adds $3M to the incentive to bring the Starship back. That might make it worthwhile, especially since two other Starships will be scrapped to supply those dozen Raptors, reducing the salvage value of the returning Starship.

I’m pretty sure it’s not worth bringing back an empty Starship if a new one costs $5M – the cost to bring it back and refurbish it is significant, and I bet Mars would pay $25/kg or even $50/kg for 3mm stainless steel plate (slightly curved) in 80-ton lots. Adding $3M might make it worthwhile.

If starships are more expensive than that, then the $3M cargo will become a smaller fraction of the total value of a returning Starship, thus less likely to tip the scales between returning all or just 1/3 of the Starships.

LikeLike

Good point.

LikeLike

People seem hell bent on not trying something new. Like there is a palpable fear of what Musk is doing. Like his push for stainless steel over advanced composites. He is open to counterintuitive thinking where an entire industry has its needly stuck in a groove. I think the primary reason his fans like him so much is that he has no fear of failing. He embraces it and welcomes failure. Like Edison wouldn’t stop trying with the lightbulb. Eventually he got it. Stubborn tenacity and the ability to actually make failing a positive thing. Starship is innovative in uniquely backwards ways that defy conventional thinking. Thanks for this economic look at it.

LikeLiked by 1 person

I’d rephrase part of this as “he has no fear of failing *at first*”.

I think Elon does fear failure which is why he wants to fail early to ensure that the company mission is a success.

LikeLike

I hate to throw a negative position in a well reasoned argument. But I really don’t understand the focus on mars. Its not like a colony on mars can be self supporting so why not do all the learning necessary for how to construct, build, maintain on something a lot closer to home and use that both in reducing cost of long distance exploration into asteroids (mining) and other destinations.

Someone has to pay for all this and i would want to see a goal that is perhaps a more practical step towards payback. This doesn’t invalidate starship. If anything it makes it more important.

If mars can be shown to have something valuable enough for a colony via exploration then build there. But why go there to build a colony until you can justify its existence. Whereas you can prove all the technology on the moon at a lower cost and much shorter timescale.

LikeLike

I’ve got other blogs on this topic.

LikeLike

Their vision is for Mars to become self sustaining. The Mars surface environment lends some useful properties, such as a relatively moderate temperature, which reduces energy requirements, stronger gravity, which has health benefits, and a useful atmosphere. Mars is isolated enough to create incentives which drive sustainability, while the Moon’s proximity may drive dependence on resupply, but I’d like to see the math on that, as well as a look into long term feasibility of refining local materials for construction.

LikeLiked by 1 person

For a shorter-term effort to build a small/medium-sized base, your gut intuition may indeed prove correct. However, I would recommend doing some reading on the topic of large-scale colonization (start here with this excellent blog; also check out the NasaSpaceFlight forum). There are many reasons why a colony of one million inhabitants — the SpaceX vision — is cheaper/easier to build on Mars than the Moon.

The financial incentive, for a very long time, will be individuals buying a stake in the future of humanity by purchasing work-share passage to the colony. There is historical precedent for this kind of venture.

LikeLiked by 1 person

The dream is to take a barren desert and turn it into a garden. The Moon can never become a garden and can never be terraformed because it is to small for an atmosphere. It is unlikely we can even live on the Moon long term due to the low gravity and we will certainly not be able to raise families and children on the Moon.

LikeLike

The justification is the existence of a self sustaining human presence on Mars. Your blanket statement that it can’t be done is not backed by anything other than your opinion. THE goal is to have a backup of the human race outside of the Earth. That goal drives everything Elon Musk does. Electric vehicles, solar, storage, tunneling and of course rockets.

LikeLike

Good that you are checking the numbers! hey, I have an issue to consider. It’s now clear that extended periods of low gravity can damage eyesight https://www.aao.org/eye-health/news/nasa-space-flight-impacts-astronauts-eyes-vision. Plus many other health effects – it’s an issue that will get more attention as time goes on. So what can be done? For example, if you have 2 starships flying to Mars, seems like you could connect them with a tether and have them rotate around their CG for some artificial gravity. The tether could be really long to minimize Coriolis effects. Would love to see a post on this subject!

LikeLike

And a followup – if you have three starships connected with cables, so the cables form a triangle, rotating around its center for gravity – what would happen as the solar wind blows thru the triangle? Looking at some sites on MHD power generation. Also there’s the Dyson-Harrop proposal for harnessing the solar wind. If you could generate power, maybe it could drive an ion engine of some kind…

LikeLike

Have seen this outlined at https://www.youtube.com/watch?v=3CRiJTJikjk, then https://www.youtube.com/watch?v=WXBsQlRsYdA, and most recently at https://www.youtube.com/watch?v=SMj9NQDn07A

LikeLike

A very interesting argument. eg. on the economics of fuel production on Mars.

You say “Transporting that much fuel [1200 tonnes] to Mars, in the absence of a plant, would require 12 tankers and a long hose.” – Is that landing the fuel on Mars to refuel on the surface of Mars ?

Won’t it be cheaper to only land enough fuel to get the Starship back into low Mars orbit, and transfer the rest of the fuel there ? Then each tanker might be able to deliver a little more than 100 tonnes of fuel but more importantly the returning Starship might only need about half the fuel once its in Mars orbit to do a trans-Earth injection ?

LikeLike

Do the math and let me know. Mars orbit rendezvous might save 2 tankers.

LikeLike

Would using a nuclear energy plant to run the fuel plant on Mars be more efficient? And maybe easier to deploy and less vulnerable to storms and dust?

LikeLike

Yes, if you can get one.

LikeLike

I also think that a gas turbine power plant could be justified if there is sufficient methane and oxygen in storage. We’d have to run the numbers if the mass and cost is better than shipping the equivalent amount of battery storage.

LikeLike

Or fuel cells. Unless you need the heat.

LikeLiked by 1 person

Great article and I wish I had the time to dig into the numbers this much.

I suggest that the switch from composites to steel is another factor that favors larger Starships.

Cheaper construction means SpaceX can afford to have more steel Starships on Mars in advance of humans.

Other factors include the size of what can be shipped. Less set up on Mars. Potentially could have a Starship be a propellant plant.

LikeLiked by 1 person

“The bigger the better” only goes so far. In the extreme case, if you make one huge mountain of a rocket, it’s a prototype. So it’s as expensive as a prototype. Without trying to run any numbers, Starship sounds as though it’s likely to be about the right size — if the Martian city is as well funded as we hope. If Starlink is a bit less lucrative, or if the costs don’t come down as far as we hope, so that the whole thing has to be scaled down and autarky takes a few extra decades, then the optimal size of the rockets presumably would be correspondingly smaller so that they still get the full benefit of mass production.

LikeLiked by 1 person

Why not use Phobos as a staging ground for missions to Mars? In the initial stages of exploration/scouting, you send down only what you need. You don’t need 100, 200 tons on the Martian surface, not all at once, during those first few missions.

LikeLike

Why use it?

LikeLike

Angry Astronaut outlines why here: https://www.youtube.com/watch?v=EPp-4v1Lj_A

LikeLike

I wonder if the propellant plant equipment could be miniaturized and more or less permanently installed in every starship. This way, each starship lands, sets up solar panels, and immediately starts manufacturing propellant for it’s own return trip, filling its tanks directly.

This would negate the need to carry heavy insulated tanks to Mars. Plus it would probably be easier and faster to get the plant up and running.

LikeLike

Then detach and leave behind the unnecessary mass before leaving?

LikeLike

Just one Starship tanker launching three times a day from one of SpaceX’s current pads translates to over 50,000 cancelled or delayed flights per year. It might pay for SpaceX to continue carrying enough military and spy payloads on those launches to guarantee administration support when the relevant agencies start duking it out.

LikeLike

Elon has hinted that the next-generation Starship will have a diameter of 18m, suggesting that the current model is the mini-version :).

I think that $5m a pop is small enough to leave a majority of Starships on Mars as scrap. Only the pricy Raptor engines warrant returning, and they will not be of much use on Mars. So only one cargo-version and enough crew-versions for returning people need come back.

The economics of re-use was much more stringent when the construction needed carbon fibre for the pressure vessels. Stainless steel has reduced the cost significantly.

I think a few left behind for local transportation is a good idea, and others can be re-purposed for robotic scientific missions to Phobos, the asteroids, or Jupiter.

LikeLiked by 1 person

I think scrap on Mars will be quite valuable. If transport cost is comparable to purchase price for various kinds of high-tech machinery, any high-mass components that are relatively easy to make from stainless steel can be left out, and that cargo capacity can be used to send other stuff.

LikeLiked by 2 people

It’s true that moving the obligatory starship reuse slider greatly reduces need for power and water, and greatly increases availability of stainless steel.

LikeLike

I think that other Starship components, such as the Tesla Model S batteries and the motors driving the fins, will have a great value on Mars. There should be a priority to send makers on the early flights.

LikeLike

Two components of finance that often confound both intuition and simplified calculation are option value and the time value of money. If it’s close, a Starship on Mars may turn out to be less valuable than its production cost, but more valuable than its value on Earth two years later (assuming it takes longer than the launch window to make enough fuel, so some would have to go back at the next one). On the other hand, having a Starship on Mars gives you the flexibility to use it or scrap it later. And making fuel later means you can use the scarce local labor for other stuff first when it’s most valuable. The implicit interest rate will probably be pretty high.

LikeLiked by 2 people

NASA technology exists today for a nuclear/electric engine that would speed the trip and reduce the cost. That engine could be stuck on the end of a long “pole” and act as a tug back forth between destinations. Realistically, less than 8 years. You still need the SH to get to orbit and the SS for transport and landing. There are many other advantages to this methodology but I’ll leave those to the reader.

LikeLike

How about this alternative to nuclear? With all that cryo in the tanks, we have access to superconductivity – the high-temp variety works in LOX or liquid methane. You can store power in a coil, either linear solenoid or toroidal – search Superconducting Magnetic Energy Storage. I think you can store a lot of power, pre-loaded before launch. If you add some plasma thrusters to the starship, that might reduce the time to Mars by quite a lot!

LikeLike

What’s the energy density like compared to methane and oxygen?

LikeLike

I don’t know the energy density – the calculation would be a challenge – all I find online is for terrestrial applications that need power for cooling. Here’s a paper about SMES storage on the moon that’s closer – https://www.hou.usra.edu/meetings/survivethenight2018/pdf/7001.pdf

You’d want a toroidal design to minimize Lorentz forces; I’m thinking this would sit inside the small LOX tank in the nose of the starship. With the large volume available it should be possible to store a lot of power – megawatts? Limited by high-temp superconductor’s quench at high magnetic fields. This might be a better fit as a replacement for the battery used by Rocket Lab’s Electron rocket…

LikeLike

Rather than miniaturized, a space only full or even over sized variant for transport that does away with all the landing mass might be good. Would suggest cargo/personal exchange depots in orbit. Ends up looking like STS.

LikeLike