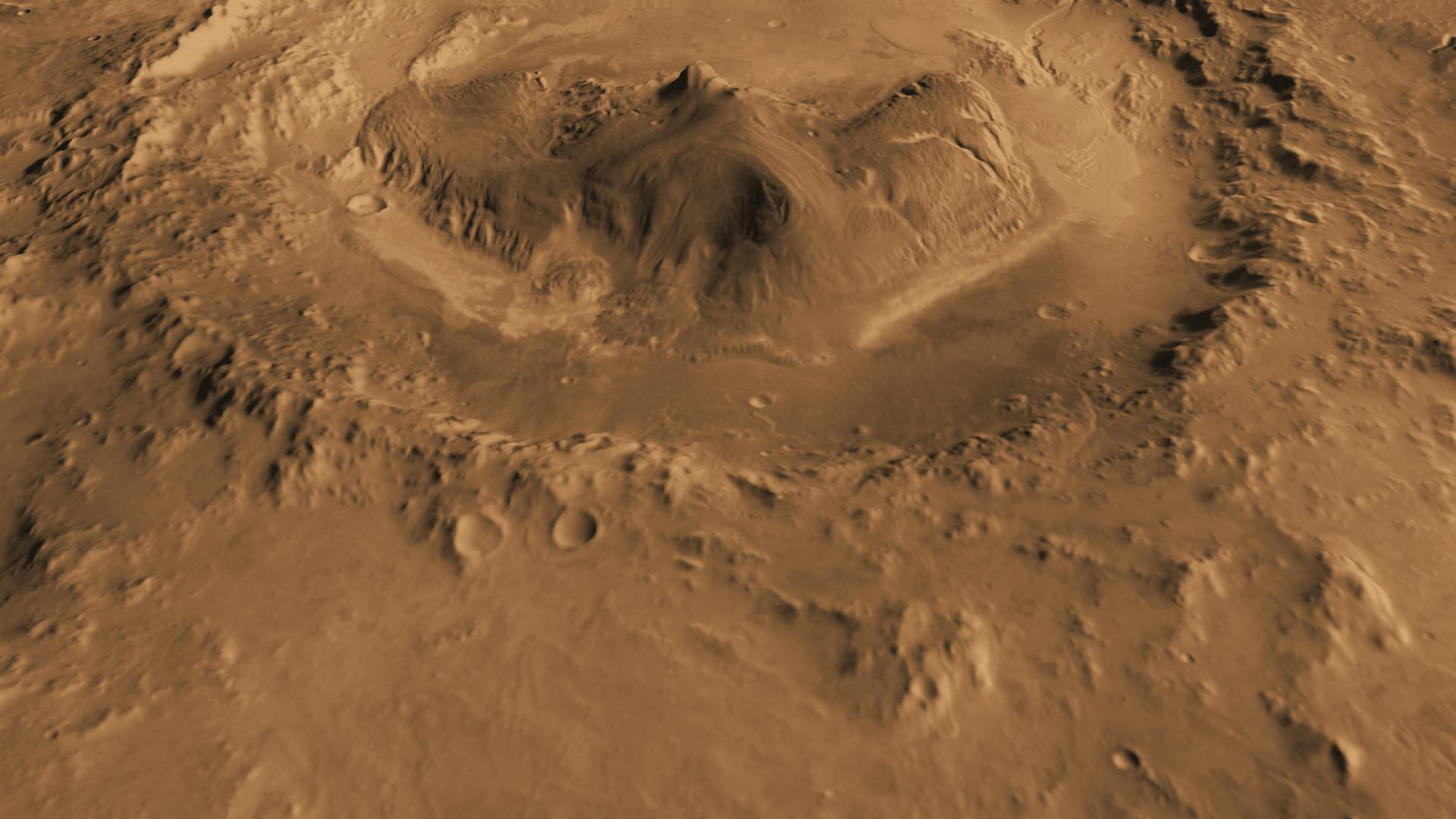

I always prefer to start talks with a recognizable image. In this case, this is a Mars Global Surveyor image of Gale Crater, looking south. The crater is about 150km wide, and the Curiosity Rover is currently driving around near the right hand edge of the central mound.Although I’ve probably seen this photo a thousand times, I only just noticed the Pancake Delta feature, just right of center at the top of the image.

I’ll start with just a bit about me. I have many interests, though I’m formally trained in physics. I earned my PhD at Caltech in 2015, studying gravity in an effort to understand warp drive. Since it turned out to be impossible, I switched to working on the Hyperloop, where I was the levitation engineer, and more recently I’ve moved to JPL, where I work on GPS instruments. These pictures show me exploring the remnants of Siberian industry, a Tesla coil I helped build for Burning Man, and pointing at the Great Unconformity, a billion year gap in the geological record visible at the bottom of the Grand Canyon.

This is also the place for the great disclaimer, beginning with the obvious stuff. It is a great honor to be here speaking to you all, but I must stress here I represent my own views and research, not that of my employer!

Second, I don’t have a crystal ball. I don’t know for sure how to build a city on Mars. But this applies to most of us. We are all mostly not doing Mars settlement full time. Instead, we come together at events like these to share our ideas and enthusiasm and then spread it like the conference flu.

Finally, this talk/blog is derived from a book on the subject available gratis at: www.caseyhandmer.com/home/mars/ , also available on Amazon at https://www.amazon.com/How-Industrialize-Mars-Strategy-Self-Sufficiency-ebook/dp/B07GN3BJX3/ for the princely sum of 99c. This work is a hobby of mine, it’s not my main gig, and my principal goal is to develop and workshop these ideas and disseminate them as widely as I can.

The goal here is to think systematically about visions of the future. It’s to inspire a more vibrant, rigorous level of discourse. It’s to help us find ways to find the right questions, questions that help us find useful answers.

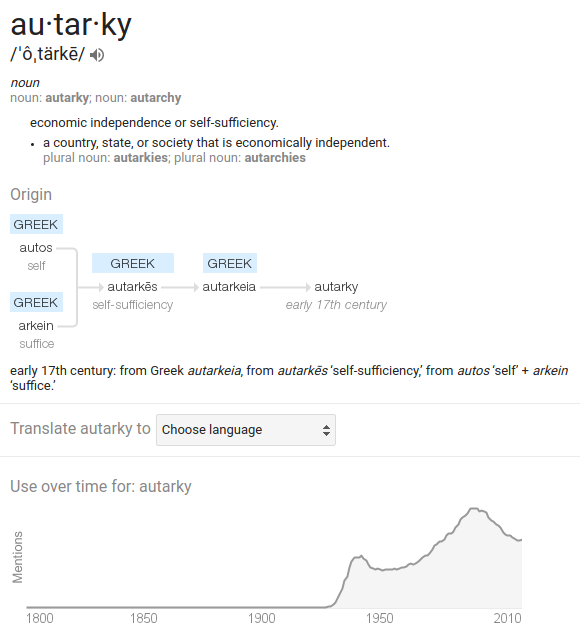

Let’s begin by defining autarky. It means economic independence or self-sufficiency.

Google trends shows that this word became very important in the 1930s when impending total war in Europe demanded industrialization for survival. Even though the word had been around since the early 17th century, it was the second world war, or the war of machines, that drove home the importance of industrial self-sufficiency.

The Martian, with Matt Damon, is one of my all time favorite films. When we think of self-sufficiency on Mars, we think of growing potatoes. But what would have happened to Watney without a ride home? The book is quite explicit about this. Even if he had plenty of supplies? Even with a thousand qualified friends and greenhouses more like the incredible farms in Holland, which have the highest productivity on a per-area basis on Earth? Death is inevitable.

In the book of The Martian, Andy Weir writes that Watney depends on life support machines, including an oxygen generator, water reclaimer, and pressure vessel, to survive. These machines were made on Earth and beyond a handful of very basic repairs, cannot be built or maintained in space, and will not last forever.

Unlike the popular but flawed traditional colonial picture, humans cannot survive on Mars with 40 acres and a donkey. Like European geopolitics in the 1930s, survival in such an inherently hostile environment is simply not possible by analogy with the US history of rugged agricultural pioneers on the frontier. In fact food isn’t even the first thing to be produced locally, being rather hard to grow without lots of related infrastructure.

It’s worth stating that while self-sufficiency for a Mars city is a worthy goal, in all but the most catastrophic scenarios, Mars and Earth would continue to trade essential parts. In the early days of the Mars city, actuaries will be able to calculate the consequences of supply interruption, just as they do for remote outposts and bases on Earth. Although manifests will be designed to minimize the disruption caused by a low level of supply interruption, total isolation will inevitably result in death after a few months or years. As the city develops greater industrial capacity, this grace period will gradually extend until the point where isolated survival is possible indefinitely, even though it would be far from optimal! The capacity for indefinite isolated survival is autarky.

What is the alternative to agricultural analogies? How can we think systematically about industry in space?

I would hope that my readers become very familiar with Cody Reeder! He has one of the most incredible YouTube channels: Cody’sLab. On this channel, he demonstrates the basis of a lot of primary production, including mining, farming, prospecting, and chemical purification. But even a thousand Codys would not survive very long on Mars.

Unlike Mark Watney, Cody has chemical and technical expertise adequate to build the necessary equipment from scratch. But while a thousand Codys could probably make *anything,* they could not make *everything* faster than the rate at which it breaks down in normal use. Indeed, if you watch the videos about his ranch, just keeping all the tractors and trucks running, in Utah with breathable air and access to McMaster-Carr, is sometimes pretty tough.

It is simply not enough to grow some food. Living on Mars is more like living indefinitely in a submarine. It will require automated manufacturing and, among other things, lots of metal. So let’s think big! Really big!

This is Australia’s main steel works, BlueScope Steel, which employs 16,000 people and produces about three million tonnes a year. It takes 30 minutes to walk across, but probably wouldn’t be big enough for a self-sustaining city on Mars.

This is the Tesla Gigafactory, which is pioneering the next generation of industrial automation. The Gigafactory makes cars and batteries, but Mars will eventually need at least basic chip fabs, an advanced composites supply chain, and active industrial research.

Again, the aim here isn’t to be completely descriptive. My goal is that this helps you develop a new thought, an incisive question, or a new strategy.

This is a good point to deal with a common diversionary tactic. Wouldn’t it be nice if self-replicating machines existed? 3D printers are very exciting precisely because they offer a technological shortcut for certain kinds of manufacturing. But they are not self-replicating machines, not by a long shot. They require very carefully curated input material and can produce only a limited range of parts.

Are self-replicating machines possible? Yes! Given the right resources, biological organisms can reproduce themselves, including my favourite here, Mr Platypus, and everyone else’s favorite, e coli.

But the platypus makes eggs containing baby platypuses, and e coli produces e coli. Convincing e coli to print a CPU or the platypus to lay an air filter would be something else!

So when we think of a self-replicating machine to solve all the industrial problems, we’re really describing a self-replicating factory or process that actually can produce anything. Which is nothing less than our modern globalized industrial society, in total. At least until someone builds a matter compiler, a regular staple of science fiction and asteroid mining concepts.

So we return to the original question, how to compactify the entire industrial stack and ship it to Mars?

What sort of scale are we talking here anyway? Is this a big problem? Oh yes!

|

China, 1410m

|

Mexico, 129m

|

Turkey, 81m

|

|

India, 1339m

|

Japan, 128m

|

Thailand, 69m

|

|

USA, 325m

|

Ethiopia, 105m

|

UK, 66m

|

|

Indonesia, 264m

|

Philippines, 105m

|

France, 65m

|

|

Brazil, 209m

|

Egypt, 98m

|

Italy, 59m

|

|

Pakistan, 197m

|

Vietnam, 96m

|

Tanzania, 57m

|

|

Nigeria, 191m

|

Germany, 82m

|

South Africa, 57m

|

|

Bangladesh, 165m

|

DR Congo, 81m

|

Myanmar, 53m

|

|

Russia*, 144m

|

Iran, 81m

|

South Korea, 51m

|

Here’s a list of the 27 most populous countries. The bolded ones contain essentially a complete industrial stack, by which I mean the ability to produce, within its own borders, all or nearly all technology necessary to produce the most advanced machines, including container ships, fighter jets, rockets, computers, mobile phones, and nuclear weapons. Russia doesn’t anymore, but it did until quite recently. South Korea does, sandwiched between Japan and China. Germany does, as a hub of sorts for the rest of Europe.

These data strongly suggest that a scale in the hundreds of millions is necessary to have enough labor specialization to support a complete industrial stack, and that’s on a planet on which we have evolved to survive essentially naked. Launching one hundred million people to Mars would be a major headache.

Let’s look at some counterexamples. Economically isolated countries like Albania, Cuba, North Korea, and Iran have every reason to attempt industrial autarky, and in many cases have tried really really hard. Yet even Cuba, with 11 million people, a very benign climate, and ample natural resources, has not succeeded. Australia, with 22 million, is not even close.

I like to think that with further advances, it might be possible to achieve autarky on Mars with only a million people, after 50-100 years of transport and building. But this would not be easy.

For comparison, imagine taking Iceland in 2018, a country with 350,000 people. Without imports, Iceland would regress to 18th century standards of living within a few years.

The OOCL Hong Kong, the world’s largest containership, can carry about 22,000 containers, which is roughly equivalent to 2000 flights of SpaceX’s BFR. I estimate is at least several decade’s worth of flights. So, given only unlimited money and one containership of gear, one has to reproduce the industrial versatility if not the might of Japan in Iceland by 2050, without substantial population growth. It’s almost unimaginable. But not quite!

Let’s talk about how to increase per capita human productivity in Iceland, or on Mars, by a factor of a hundred or so. The trick is the mechanization of labor, which is related to why whales have big mouths.

Consider a pre-industrial agricultural society, such as the fields pictured above. All available energy in the form of work is derived from solar power, from photosynthesis, and all available physical labor is from human muscle. Therefore, the total output of the system is limited, fundamentally, by how much energy all the humans can consume and digest.

Yet the gap in GDP between industrialized and pre-industrialized societies is a factor of 30-60. By freeing themselves from the requirement of work of sweat off the brow, a single human can control a gigantic, usually gasoline-powered, machine, or even remotely program one, to perform labor on its behalf.

We’ve already seen that while on Earth, a sufficiently motivated, knowledgeable individual can survive in many places with no resources, an industrial Mars will require the production efficiency of a hundred million humans. The fundamental problem for industrial human societies on Mars is a terrible shortage of labor, so the solution is to automate, mechanize, and outsource non-local tasks. By how much?

Consider the manual-mechanized continuum graph. For any level of technology, there is an optimal blend of human and machine labor. Compare, for example, the manual construction of the pyramids and the rapid modern construction of a house by a skilled contractor.

As technology improves, the optimal point moves to the right, but it is *never* most efficient to completely automate something, even the construction of a moon or Mars base. Complete automation is a subset of the self-replicating machine problem. A complimentary mixture of humans and machines is the way to go.

Take for example these two drilling systems. One is eight orders of magnitude more expensive, but doesn’t need a human to “line it up”. And sometimes it breaks down for a year at a time. Perhaps NASA paid too much for the rover, and it’s only 7 orders of magnitude more expensive than a human-controlled tool?

from future import industry

How can we achieve a Japanese level of industrial versatility and power with Iceland-style population? We must grow the fraction of labor that’s automated as the base scales. For instance, if the base doubles in size every launch window, the productivity of the supporting industries must also double, without doubling their labor requirement. Instead, individual labor productivity must also double at close to the same rate.

What does increasing individual productivity by three orders of magnitude look like? For inspiration, let’s consider the development of programming languages. The answer is the sequential interposition of layers of automated abstraction between the human and the physical stuff. This approach is only cost effective in situations of profound labor shortage, such as keeping up with exploding capability and complexity of modern computers.

Computer languages have evolved some hierarchy like machine code, Assembly, C, C++, Python. Each step encapsulates another layer of abstraction between the human writer and the fundamental logical operations, allowing much more powerful things to be done with a given labor pool. But let’s not stretch the analogy too much.

The final question I want to cover is order of industrial roll out. What resources get made first? As a case study, consider this incredible open source robot arm, the BCN3D-Moveo (

https://github.com/BCN3D/BCN3D-Moveo). Mars will need a lot of robot arms, so this isn’t a bad place to start.

Here’s (the interesting half of) the BOM, or bill of materials. This is a shopping list from which the arm can be made. Broadly speaking, components fall into five groups: Structure, fasteners, bearings, motor, and power.

- Structure, which are the bones, base, and carry the weight of the arm.

- Fasteners, such as bolts, rivets, screws, nuts, clips, and so on.

- Bearings, which enable two adjacent hard parts to swivel past each other with low friction and wear.

- Motors, which provide the forces. Motors are deceptively cheap due to mass manufacture, but often require weird magnets and low sulfur high conductivity copper and other things that are hard to come by on any randomly selected part of Mars.

- Power, which includes cables that move electricity around but also printed circuit boards, control logic, microcontroller chips, and other components which are relatively cheap on Earth, light, and very difficult to make from scratch.

I tabulated the cost as a proxy for manufacturing difficulty and the mass as a proxy for transportation difficulty from Earth. While a workshop on Mars could make any of these parts, mass local manufacture will proceed in order of mass divided by difficulty of manufacture, which is the order tabulated above.

This is what you’ve been waiting for, the roadmap for industrialization. There’s a lot going on in this figure, so let’s unpack it!

On the left, I’ve ranked successive orders of magnitude of industrial “closure”, or local production capacity. Starting with oxygen, then water and fuel, plastics and some food, then masonry, structural metals, then alloys, electronics, advanced chemistry and computer processors.

On the bottom, we have population. Today, we are in the bottom left, with only robots. With local production of oxygen and fuel, humans can explore and even operate outposts like the Antarctic stations. But at some point vast quantities of cargo and humans will have to be shipped to traverse this dangerous area of potential collapse.

This area is dangerous because the population is too large to be evacuated and too small to be self-sufficient. The city traverses the graph toward the top right, such as the trajectory marked in red. Ultimately, the city has a large population and a diverse, self-sufficient industrial base.

The major primary industries deal with mining of any desired element. Because each mine will have to operate in the hostile Mars environment, emplacement of primary industry incurs a much steeper labor penalty than increasing complexification of secondary manufacturing, which can be conducted entirely inside large, pressurized, climate controlled habs.

For this reason, from the exploration phase until the cusp, marked with a purple dot, each order of magnitude of mass self-sufficiency requires more than that of people.

Beyond this point, marking the completion of a local basic material supply chain, relatively small additions of population have an outsized effect on industrial closure. I estimated the critical stage on this graph is from about 1000 people to 100,000.

The fundamental limit here is Earth-Mars cargo capacity, as illustrated by the grey lines.

Cargo capacity is determined by how fast we can build gigantic rockets here on Earth.

Today, SpaceX can build about 20 cores a year, but Boeing can build 560 737s a year, a machine of comparable complexity. So I think this is a tractable problem, within the capabilities of our current civilization.

In summary, autarky is possible, but requires a really bold vision for scale, lots of giant rockets, lots of people, lots of ongoing, though non-infinite, investment of money and effort on Earth.

What questions do you have?

This is a brilliant exposition! This also goes to why the Moon is the first choice for industrialization because of the leverage of only being 1/4 light second from the Earth. The per unit of production productivity of the humans on the Moon is probably 10x leveraged (conservatively), compared to Mars due to telepresence. There is a further leveraging effect of only being 338,000 km away. This means a more frequent and less costly supply chain.

I thank you for this exposition as it is an excellent thought piece!

LikeLiked by 3 people

Thanks Dennis. I started work on this topic in an effort to quantitatively understand relative difficulty for Mars or Moon cities in different areas. Mars retains certain advantages, including day length, geology, delta V, temperature, atmosphere, water abundance, but by the time I wrote this blog I had become less convinced that these advantages were overwhelming.

A lot depends on how useful robots can become in the near future.

LikeLiked by 3 people

When it comes to deltaV, an asteroid captured around the Moon probably comes cheapest, although starting from the martian moons gives easier to access to the majority fraction of the Asteroid Belt.

LikeLiked by 1 person

Are you including the prop required to capture the asteroid?

LikeLike

Both have their charms. I think at the end of the day that Mars is going to be important as an economic port of call for materials coming from the main belt and beyond to the Earth and Moon. I am not a strong Moon vs Mars partisan.

LikeLike

Dr. Casey Handmer,

So which do you recommend first? A Mars colony or a lunar colony?

LikeLiked by 1 person

I used to be Mars first. Now I think they’re both difficult and worthy. Increasingly, I understand that the technology that makes either possible is not mutually exclusive.

LikeLike

Yes. Moving asteroids can cost very little deltaV. Hundreds of large bodies can be moved into an orbit around the Earth by a small nudge (150-500m/s) that swings then around the moon for a lunar-assisted capture. It’s trickier for Mars but the deltaV from a moon like Phobos to a near-Mars asteroid is low in the first place (lower than from LEO to the Moon anyway).

LikeLike

Smaller dV, but prop mass is still enormous because the asteroid mass is so large.

LikeLike

The reaction mass to move the asteroid is part of the asteroid’s initial size, not part of what has to be launched from Earth.

LikeLiked by 1 person

Hope this isn’t too stupid to ask, but how are you going to make plastics and other petroleum based materials on Mars? Grease and oil for all those bearings, etc.

LikeLiked by 1 person

Synthesized from methane. Or non hydrocarbon-based.

LikeLike

Also, once a few polymer greenhouses have been set up, plants high in cellulose can be grown in them. The plants convert the carbon dioxide pumped into the pressurized greenhouses into cellulose, which in turn can be used for the producing plastics.

PHA and Rayon are polymers that can be produced from cellulose.

https://space.stackexchange.com/questions/2569/can-materials-be-found-to-make-plastic-on-mars/26601#26601

LikeLiked by 1 person

Yup, but even the most efficient plants are nowhere near as efficient as physical/chemical processes. Their main virtue is they grow themselves, given infinite land

LikeLike

This is a good question that must be asked. It boils down to understanding chemistry and the periodic table and employing innovative chemical and even mechanical alternatives where necessary.

The Martian Atmosphere contains CO2 and water contains hydrogen (H) so methane (CH4) can be created along with organic compounds such as plastics and other polymers and composites. Bacteria can also be engineered to act as molecular synthesizing factories. (https://microbewiki.kenyon.edu/index.php/Bacterial_Derived_Plastics)

In his book, “The Case for Mars” (1996, revised and updated 2011), Dr. Robert Zubrin discusses production of ethylene (C2H4) and polyethylene plastic from the CO2 of the Martian atmosphere and hydrogen either brought to Mars or electrolyzed from water (H2O) on Mars.

https://en.wikipedia.org/wiki/The_Case_for_Mars

Ways can be found to do things without grease or a petroleum derived product.

e.g. Greaseless Bearings, carbon from CO2 or organic agricultural waste

https://www.popularmechanics.com/technology/gear/a15603/super-efficient-greaseless-bearings/

Alternative carbon feedstock for the chemical industry? – Assessing the challenges posed by the human dimension in the carbon transition

by Roh Pin Lee https://www.sciencedirect.com/science/article/pii/S095965261930349X

Petroleum is a non-renewable resource. Alternatives will need to be in place on Earth when petroleum is no longer available. Many decades ago Buckminster Fuller used to refer to oil as a cosmic savings account. (Energy, Earth, and Everyone by Medard Gabel (1975, expanded and revised, 1980 ), Critical Path by R. Buckminster Fuller (1981), World Design Science Decade 1965-1975

One could challenge the scientific establishment and try drilling for oil on Mars based on the hypothesis of an Abiogenic origin of petroleum. If the hypothesis is false, the dry hole will be the most expensive one in the solar system so maybe write up the research grant as Martian mantle research.

https://en.wikipedia.org/wiki/Abiogenic_petroleum_origin

“In discussing such possible upping of living standards in global

terms, most persons will refer to the depletable nature of energy resources now sustaining our present high standard industrial nations. As previously mentioned these operate largely on ‘capital’ rather than ‘income’ resources – on the finite reserves of fossil fuels rather than on the relatively in-finite and direct tapping of the great universal energy cycles of solar, tidal and waterpower energies. Redirection to use of recycling ‘income’ may then be the second stage priority in the world energy picture. It will phase in with the more urgent redistribution of industrialization.” R. Buckminster Fuller, pg. 28, World Design Science Decade 1965-1975 Phase 1 (1963) Document 1: Inventory of World Resources Human Trends and Needs

LikeLike

As low-level programmer I have to admit something.

Python is a very good example of something that is not self sustaining and probably showcases preview of problems.

1. You don’t generally write OS kernels or device drivers in Python. That wouldn’t do. And what python program would be without underlying C runtime/os/kernel/drivers? Something like human without oxygen and food? Somethinh like machine without power supply?

2. Actually, there is “layering hierarchy”. Low level ppl can get things done without high level stuff. They bootstrapped industry, proving it viable. High level languages on other hand either can’t deal with low level details at all, or it quickly turns into worst nightmare. Morale of story? We need both hammer and HDD and HDD by no means is upgrade of hammer. So python by no means upgrade to C.

3. High level abstractions lose low level details and eventually end up being either unreliable due to inability or unwillingness to deal with e.g. low level errors, and/or unable to have fine-grained control over its runtime environment details. This leads to bizarre and usually unexpected failure modes. And good luck to, say, write reliable, real-time bounf “motor control” firmware for MCU in python. While not theoretically impossible… I wouldn’t fly plane controlled by software written like this. Same goes for e.g. life support systems and something. Efficiency is good, but just that alone could quickly bring to downfall. What’s saving time on life support system development worth of, if it suddenly fails bizarre way, likely killing someone who relied on it? Same for industrial control, especially “last line of defence” (where hard-real-time MCUs kick in to prevent total blow-up and so on and at least a manageable shutdown, even is most things around failed).

4. There is hardware. And what software in system would be without hardware and firmwares around? Just some useless words and dead metal? I’d say that part is rather “interesting”. It brings some “magic” I like. When power just applied, dead metal have to become “live”. Its rather interesting and tricky process. Somehow on most existing CPU designs it happens in very limited and specific environment. Even C isn’t always does, sometimes it still needs at least some bits of assembly that are beyond of C abstractions. HW development usually happens in specific HDLs, or more recently sometimes in very specific subdialect of C(++).

I guess some of outlined issues resemble what you wrote there. Being able to write high level scripting to robotic facility maybe good, but it only ok for overall orchestration but would not do when you need reliable, safety-critical, real-time system, last line of defence, and so on.

Also I don’t fully get prob of oxygen and water. If you have water supply and power source, you can do electrolisys and get oxygen. Byproduct hydrogen can eventually become useful as fuel. This process is fairly simple, known from XIX century or so and doesn’t really needs advanced techs. Same for water, given enough power one can e.g. distill “bad” water into quite clean one. It fairly simple process either, doable even with early XX century techs. The more complicated part is automated control of life support systems and adjusting chemical composition of these though. I guess “core” of such machinery should be doable quite fast. And at the end of day, if you can’t afford decent control and automation, well, in worst case humans can do that manually, as duty. I even know some facilities where humans still do control of comparable processes in old-school manual ways.

Interestingly options like trying it the other ways like e.g. bootstrapping alive ecosystem as replacement or complement to technological approach look nice. But also likely very perilous and unexplored. Nobody knows how it would perform in unusual environment – and if something bad comes out… humans haven’t fully defeated, say, AIDS even on Earth. Imagine totally new virus or bacteria developed in such ecosystem. What colony is supposed to do at this point? Especially autonomously? I wonder how it going to be addressed, btw.

LikeLike

I’ve always been fascinated by the manual-mechanized continuum graph you mentioned in this article, but can’t quite find literature talking about anything similar.

Is the manual-mechanized continuum graph an original idea of yours?

Or were you inspired by a paper you’ve read previously?

LikeLike

I think I made it up. But similar concepts have been around forever.

LikeLiked by 1 person

Very nice article.

When talking about complete autonomy what you are writing makes a lot of sense – if you need to make a microchip from raw materials that you had to mine yourself and be able to produce all the equipment in the production line yourself it will require a substantial population.

However, I would expect a very high level of autonomy can be reached when certain essential equipment (with sufficient redundancy) and raw materials are brought along.

A level where the colony (outpost) should be able to survive years without receiving new shipments.

With an outpost of 100 to 1000 people and some sophisticated equipment it should be possible to create circuit-boards, 3d-print complex metal and plastic parts and produce masonry from local resources.

Raw materials such as different types of metals would need to be stockpiled and recycling would be very important, but survival of the outpost should be possible for extended periods of time at this stage I would think.

I agree that the phase going from lets say 3k to 100k will be a difficult one – the outpost will probably remain at a level below this for quite some time until some breakthroughs are made to facilitate growth from there.

LikeLike

1000 people could make almost anything but they wouldn’t have enough efficiency to make things fast enough to keep up with their natural breakage rate.

LikeLike